WELCOME

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

TO OUR STORE

SEPARATOR DIRT FILTER WITH MAGNET 3/4 DN20 COMPACT R146CX004 GIACOMINI

Gross

zł392.73

Sold: 2Gross

0/5

PRINCIPLE:

Water flows into the pollutant separator and then is directed to the cyclone chamber where the created vortex motion facilitates the separation of dirt particles, additionally located in the flow magnet captures metallic impurities and iron oxide. The strainer located at the bottom of the cyclone effectively traps contaminants (300 μm) at the bottom of the separator chamber. The dirt separator has a screw at the top to vent the chamber at first start (see section "Mounting")

The separator can be cleaned without dismantling and/or shutting down the system by opening the drain at the bottom of the separator after removing the magnet from the sleeve. Unscrew the magnet and then pull it up (see section "maintenance")

MAINTENANCE:

How to clean the dirt separator During system operation, debris accumulates on the surface of the magnet housing and on the bottom of the separator. The separator does not need to be dismantled and switched off during cleaning, but we recommend that these operations be carried out without flow inside the separator (via the shut-off valve). To clean the separator and remove debris, follow these steps:

▶️ Cut off the flow with a ball valve

▶️ Remove the magnet from the housing by unscrewing it counterclockwise using a 5mm Allen key. Debris accumulated on the housing will fall to the bottom of the separator

▶️ After a few minutes, unscrew the cap from the drain valve and place it at the bottom in the valve socket, then turn left to open the drain valve and empty the debris from the separator settling tank

▶️ When the contaminants have been removed, close the drain valve and mount the magnet back into the housing by screwing it clockwise. The separator will start working normally

For more thorough cleaning, proceed as follows:

▶️ Close the water supply on the ball valves before and after the separator to prevent water from flowing inside the separator

▶️ Unscrew the base of the dirt separator counterclockwise

▶️ Remove the strainer from the separator and clean it

▶️ Place the filter back and screw the base tightly to the separator

Share on:

PRODUCT CHARACTERISTICS:

✅ Compact magnetic contaminant separator with cyclone chamber and filter

✅ Equipped with adjustable inlet/outlet connections GZ ISO 228, rotating drain, neodymium magnet N35H (13000 Gauss) in brass sleeve

✅ Body made of nickel-plated brass CW617N - UNI EN 12165

✅ Cyclone chamber made of glass fibre reinforced synthetic material (PA66GF30)

✅ INOX steel filter (AISI 304) with filtration accuracy of 300 μm

✅ EPDM gaskets

PRINCIPLE:

Water flows into the pollutant separator and then is directed to the cyclone chamber where the created vortex motion facilitates the separation of dirt particles, additionally located in the flow magnet captures metallic impurities and iron oxide. The strainer located at the bottom of the cyclone effectively traps contaminants (300 μm) at the bottom of the separator chamber. The dirt separator has a screw at the top to vent the chamber at first start (see section "Mounting")

The separator can be cleaned without dismantling and/or shutting down the system by opening the drain at the bottom of the separator after removing the magnet from the sleeve. Unscrew the magnet and then pull it up (see section "maintenance")

MAINTENANCE:

How to clean the dirt separator During system operation, debris accumulates on the surface of the magnet housing and on the bottom of the separator. The separator does not need to be dismantled and switched off during cleaning, but we recommend that these operations be carried out without flow inside the separator (via the shut-off valve). To clean the separator and remove debris, follow these steps:

▶️ Cut off the flow with a ball valve

▶️ Remove the magnet from the housing by unscrewing it counterclockwise using a 5mm Allen key. Debris accumulated on the housing will fall to the bottom of the separator

▶️ After a few minutes, unscrew the cap from the drain valve and place it at the bottom in the valve socket, then turn left to open the drain valve and empty the debris from the separator settling tank

▶️ When the contaminants have been removed, close the drain valve and mount the magnet back into the housing by screwing it clockwise. The separator will start working normally

For more thorough cleaning, proceed as follows:

▶️ Close the water supply on the ball valves before and after the separator to prevent water from flowing inside the separator

▶️ Unscrew the base of the dirt separator counterclockwise

▶️ Remove the strainer from the separator and clean it

▶️ Place the filter back and screw the base tightly to the separator

MATERIALS:

✅ Body and inlet/outlet connection: nickel-plated brass CW617N-UNIEN12165

✅ Cyclone chamber: Glass fiber reinforced nylon 66 30% (PA66GF30)

✅ Filter: AISI 304 stainless steel

✅ Sealing: EPDM

✅ Magnet: neodymium (N42H) for 3/4" dirt separator (red magnet)

TECHNICAL DATA:

✅ Operating temperature range: 5 ÷ 90°C

✅ Maximum working pressure: 10 bar

✅ Liquid: water, glycol solutions (max. 50%)

✅ Size: 3/4" GZ

✅ Filtration accuracy: 300 μm

✅ Neodymium magnet: 13000 Gausses (red magnet)

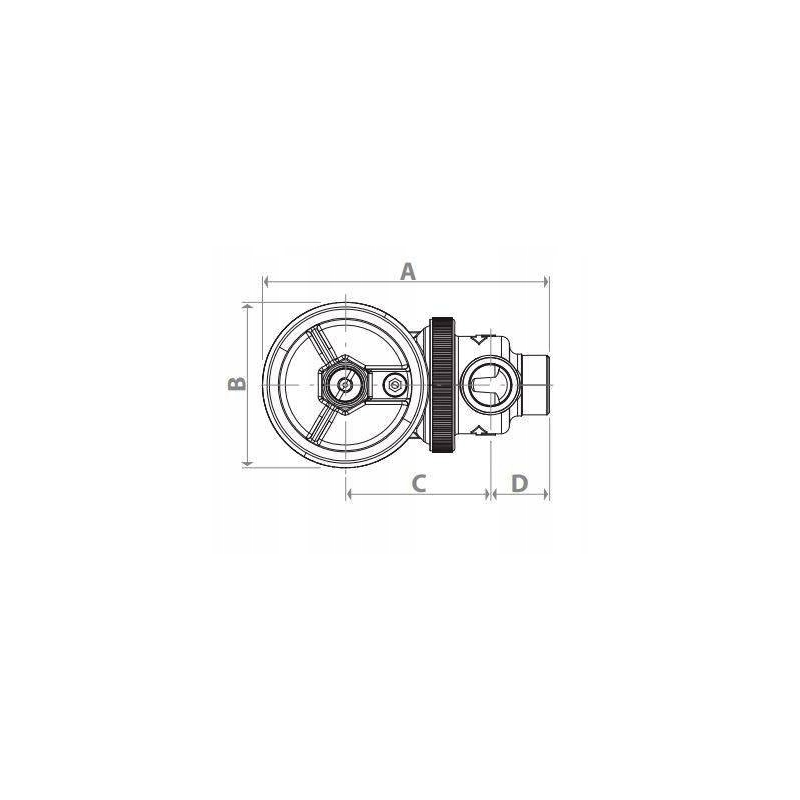

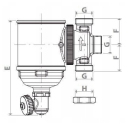

Technical dimensions:

▶️ A: 126.5 mm,

▶️ B: 73 mm,

▶️ C: 64 mm,

▶️ D: 26 mm,

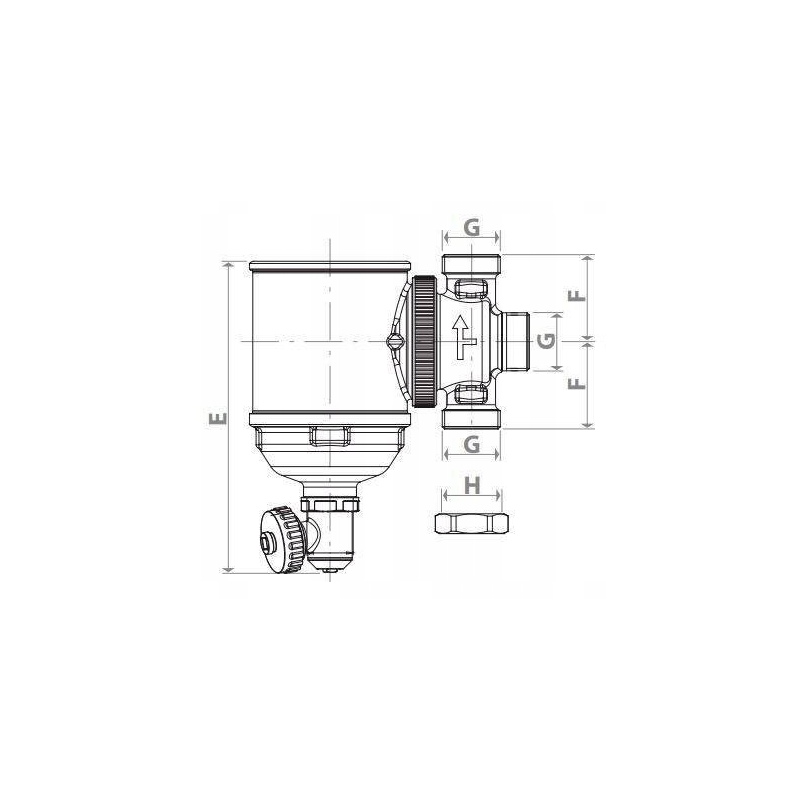

▶️ E: 141 mm,

▶️ F: 39.5 mm,

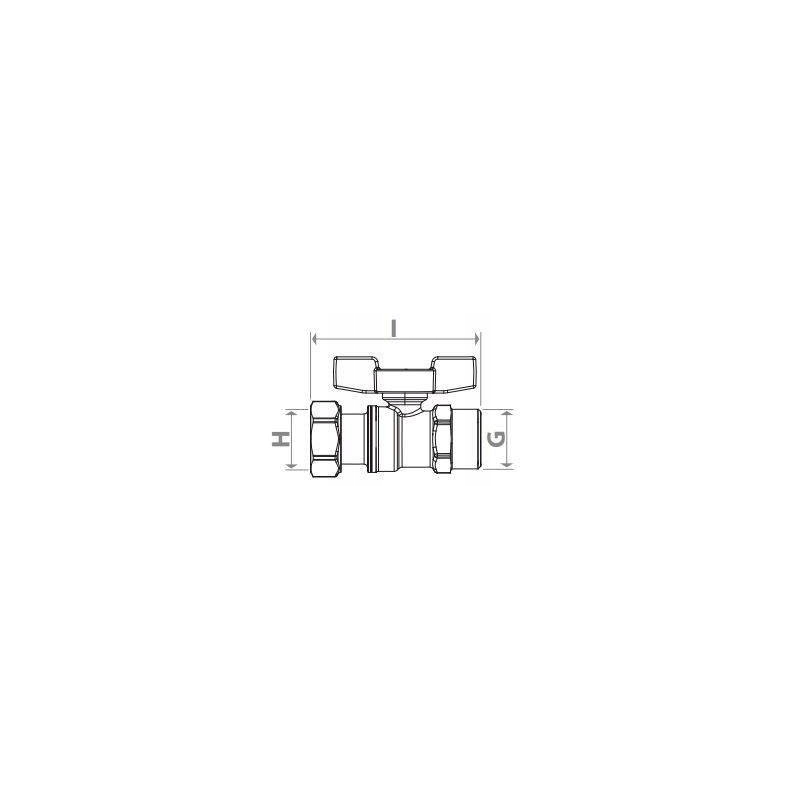

▶️ G: G 3/4" M mm,

▶️ H: G 3/4"F mm,

▶️ I: 75 mm,

▶️ L: 33 mm,

▶️ M: 49÷62 mm

▶️ Product type: PIN SEPARATOR

▶️ Manufacturer no: R146CX004

Specyfikacja

| Status | New |

|---|---|

| Brand | GIACOMINI |

Comments (0)

Your review appreciation cannot be sent

Report comment

Are you sure that you want to report this comment?

Report sent

Your report has been submitted and will be considered by a moderator.

Your report cannot be sent

Write your review

Review sent

Your comment has been submitted and will be available once approved by a moderator.

Your review cannot be sent