WELCOME

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

TO OUR STORE

BOILER PELLET STOVE ALFA II 12KW 5TH CLASS ECODESIGN DEFRO

Gross

zł21,769.27

Sold: 2Gross

0/5

BOILER PELLET STOVE ALFA II 12KW 5 CLASS ECODESIGN DEFRO

Share on:

ALFA II – Pellet boiler with an innovative central burner and extensive equipment giving the user many benefits and comfortable operation.

♻️ Compact design of the boiler with the possibility of significantly enlarging the pellet tank (PLUS version)*.

♻️ The heat exchanger has a built-in automatic cleaning system and an automatic ash removal kit.

♻️ Equipped with the so-called central burner ensuring effective pellet combustion. The burner with the automatic cleaning function guarantees reliable operation of the boiler.

♻️ The burner is factory-equipped with 2 igniters. TSS Twin Park System.

♻️ Ceramic partitions are placed above the furnace, and the heat is used in the rear part of the boiler to heat the vertical fire tubes, recovering heat. Fire tubes are equipped with economizers, which are also used for automatic cleaning.

♻️ Vacuum sensor to monitor the correct process in the combustion chamber.

♻️ Exhaust fan eliminating the problem of improper chimney draught, stabilizing the boiler operation.

♻️ Operation of the boiler thanks to the APC CENTER controller guarantees intuitive operation and self-control of the boiler. The controller allows you to operate 6 pumps. 2 mixing valves and a built-in internet module.

♻️ It has a hydraulic set with a circulation pump and a thermostatic valve as corrosion protection for the boiler.

♻️ The pellet level sensor used in the hopper allows you to control the fuel level, and in the event of a fuel shortage, there is no need to re-ignite the boiler after refilling.

♻️ It is possible to expand the combustion control system with a Lambda sensor, which optimizes the combustion process and ensures even higher boiler efficiency with minimal exhaust emissions*.

⚡ Heat exchanger made of certified high-quality steel

⚡ High thermal efficiency in the range of 91.2 to 93.2% due to increased heat recovery from the flue gas

⚡ APC CENTER controller operating 6 pumps /central heating, hot water, circulating, floor /. Control of two mixing valves; viewing and changing the parameters of the main controller ONLINE via the built-in Internet module with RJ-45 socket

⚡ The boiler is adapted as standard for installation in a closed system, provided that the protection is installed in accordance with the boiler's DTR

⚡ Exhaust fan eliminating the problem with the chimney draught and stabilizing the boiler operation

⚡ Vacuum sensor to protect against improper combustion process

⚡ Twin Spark System – pellet burner equipped with two igniters as standard

⚡ A fuel reserve sensor in the storage tank stops the boiler operation with a minimum fuel level. After re-charging the fuel, there is no need to repeat the firing procedure, and the boiler switches to automatic operation

⚡ Ceramic catalysts stabilizing the combustion process

⚡ Self-ignition fuel system

⚡ Central pellet burner with automatic cleaning function as standard

⚡ Automatic heat exchanger cleaning and ash removal system as standard

⚡ Hydraulic kit with circulation pump and thermostatic valve as boiler protection against low return temperature

⚡ An intelligent algorithm that optimizes the combustion process and ensures the highest boiler efficiency with minimum exhaust emissions, in the full power range.

APC CENTER

CONTROLLER FEATURES:

- pump control (6): central heating, hot water, circulation, floor and 2 additional pumps.

- control of two mixing valves with their assigned circulation pumps.

- automatic firing and shutting down of the boiler by the www.emodul.pl (also available in remote control via the Internet).

- weekly control.

- possibility of connecting a room controller, traditional or via RS cable communication, a dedicated controller: DEFRO SPK LUX.

- possibility of connecting the ST-65 GSM module.

- measurement of pellet consumption by means of a sensor placed in the hopper, which reads the pellet level.

- possibility of controlling 2 additional mixing valves using the DERFO MZ module.

- touchscreen colour graphic display (selectable menu display).

- temperature sensors: central heating, hot water, valves, external return and exhaust gas.

- photoresistor (flame sensor, controlling the quality of the flame).

- it has thermal temperature protection of the boiler – STB sensor.

- It has thermal protection of the burner.

- control of operation by exhaust fan.

- remote control of mi.in.: temperatures, settings, technical parameters, work history, alarms and statistics by means of on-line cooperation via the Internet module.

⚙️ Power range kW 3.2-12.2

⚙️ Heating surface m2 1.4

⚙️ Heated area m2 up to 150

⚙️ Single Fuel Charge (STD/PLUS) kg ~85 / ~145

⚙️ Efficiency for nominal power % 90.7

⚙️ Minimum power efficiency % 91.2

⚙️ Energy efficiency class A+

⚙️ Max. permissible working pressure bar 3.0

⚙️ Required exhaust thrust mbar 0.13

⚙️ Supply water temperature min/max °C 65/80

⚙️ Boiler weight kg 357

⚙️ Boiler water capacity L 55

⚙️ Diameter of supply/return port inch GW 1"

⚙️ Drain port diameter inch GW 1/2"

⚙️ Flue diameter with fan reduction mm 130

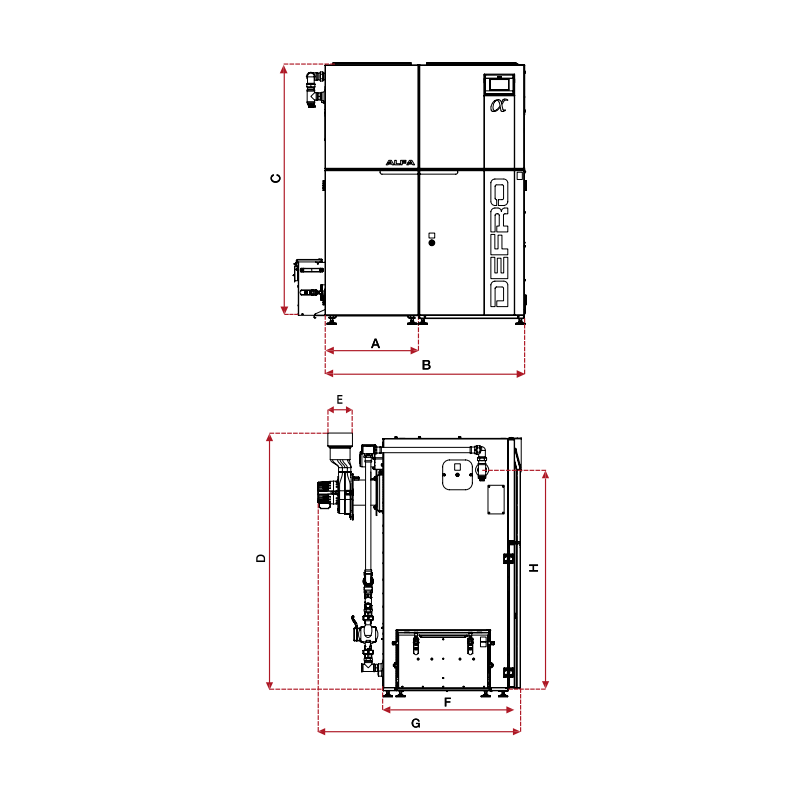

BOILER DIMENSIONS (mm)

A 470

B (STD/PLUS) 1176/1496

C 1263

D 1223

E 130

F 775

G 1025

H 1088

Specyfikacja

| Status | New |

|---|---|

| Brand | DEFRO |

| Power in KW | 12 |

Comments (0)

Your review appreciation cannot be sent

Report comment

Are you sure that you want to report this comment?

Report sent

Your report has been submitted and will be considered by a moderator.

Your report cannot be sent

Write your review

Review sent

Your comment has been submitted and will be available once approved by a moderator.

Your review cannot be sent